This saw has been designed for precise cutting of tubes and pipes in just seconds.

For more than 40 years construction companies rely on the standard set by Orbitalum in the industrial prefabrication of pipeline systems: From the chemical, biotechnology, pharmaceutical, food and beverage industry to the energy plant construction and shipbuilding.

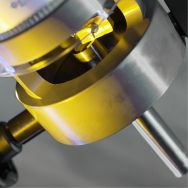

Perform economical cutting and beveling with technology made by Orbitalum Tools! Cutting and beveling high-alloy steel (stainless steel), low- and unalloyed steel, plastics, casting materials and non-ferrous metals in just seconds, using the "Planetary Cutting" method.

Innovative saws from Orbitalum Tools for cutting and beveling of tubes and for cutting off elbows (also for thin-walled stainless steel) in just seconds. The perfect preparation for orbital welding! Easy to use, powerful and compact saw with low weight – our new GFX provides even more outstanding features.

A mobile, powerful and flexible tube cutting machine for use on construction sites, that’s what the PS saw from Orbitalum Tools stands for. This tube saw convinces not only with it's burr-free, right-angled and deformation-free cutting results, but also with its low weight. At the same time its problem-free and simple usage as well as its unbeatable price are the prime factors among it users.

The RPG series represent ease of use and particularly economical clamping. The capabilities of our RPG range include squaring (I-seam) thin-walled stainless steel tubes and micro-fittings, as well as unalloyed and low-alloyed steels, aluminum and titanium. The machines fit excellently in the hand as their size and weight can hardly be surpassed. Users can select the appropriate clamping shells from the range of accessories for each diameter.

The solution when space is limited! Only very limited space is often available between welded boiler pipes. The compact body design of BRB machines is optimized for the application in question to provide the operator with the best possible access in every position and is therefore the best solution for pipe end and tube sheet joint preparations in boiler, tank and apparatus construction.

The portable pipe end preparation machines REB are setting new standards in the weld prepping of metal pipes. Take advantage of this latest technology to reduce your tool and manufacturing costs and to increase your productivity when making precise and reproducible weld prep profiles, both on site and in the prefab workshop.

The best solution for a precise and fast preparation of tungsten electrodes. The perfect hand-held grinder for cutting, grinding and planing electrodes which are used in WIG/TIG welding machines.

Compact power supplies for mechanized TIG orbital welding with a currently unique operating concept and a whole series of other special technical features. In connection with an ORBITALUM orbital weld head, the user is being offered an extremely innovative and economical welding system.

In addition to the reliable automatic programming which generates welding parameters by entering the tube diameter, wall thickness, material and welding gas all ORBIMAT CA models also include a FLOW FORCE function to reduce the pre-flow gas time when the weld heads are closed in the standard model and BUP control function with controllable, position-dependent tube internal pressure control as an optional extra.

It doesn't get any smaller or more effective than this: Thanks to its extremely narrow construction the OW 12 offers a unique diversity of functions as well as a high duty cycle previously unknown in weld heads of this size through its liquid cooling. This micro weld head is a compact space-saving marvel and guarantees continually reproducible, high-quality weld seams, even with high currents. Particularly suitable for welding all common microfittings!

The OW 12 with its small-sized modules – basic machine, clamping cartridges and clamping inserts – is the ideal tool for work under tight spaces such as the semiconductor industry, aerospace, pharmaceutical industry as well as the ultra-pure water supply sectors.

Small, robust and efficient: The OW 19 is the perfect tool when the task involves connections of ultra-high-purity tubes and high-performance tubes, such as are used for example in the semiconductor industry or applications in branches in which high purity and maximum performance are imperative. Even under extremely difficult conditions and in tight spaces the OW 19 produces excellent and reliable quality!

Its extremely high endurance thanks to the intensive liquid cooling as well as its high-quality robust construction are characteristics which distinguish this micro weld head.

Easier to handle, more economical, more effective – enclosed TIG orbital welding heads with outstanding characteristics: The ORBIWELD "S" series from Orbitalum convinces by its extremely narrow design and high durability by its efficient integrated liquid cooling system.

The small dimensions of the ORBIWELD "S" series make it ideal for applications where space is very restricted, such as the pharmaceutical and chemical industry, the semiconductor, food and beverage industry as well as aerospace.

The orbital weld heads HX for compact cooling systems are setting new standards!

"HX" stands for "heat exchanger" and for the welding of pre-mounted elbows in tight pipe bundles of heat exchangers into a pipe coil. There is no other solution as effective as this one in the world!

The ORBIWELD TP series offers outstanding features in terms of design and functionality: An extremely compact design has been achieved thanks to the drive motor that is fully integrated into the housing.

The new orbital TIG weld head from Orbitalum for manufacturing pipe-to-pipe-sheet connections guarantees extremely short production times of industrial heat exchanges at constantly high reproducible quality. Also excellently suitable for repair, maintenance and servicing work.

Welding heat exchanger tubes particular effectively and easily: With our new TX 38P for automated TIG orbital welding you can now accurately and precisely weld tube sheets with heat exchanger tubes, such as thousands of welded joints on cooling tubes.

Our P series is characterized by special design features intended to ensure easy handling combined with a high level of economy and functionality. With extreme precision, these tube-to-tube-sheet orbital weld heads will produce several thousand weld seams at constant quality.

With this TIG weld heads, it is no longer a problem to weld tubes to tube-sheets with the highest of accuracy and consistent quality

This ORBmax residual oxygen meter sets a milestone for fast, exact detection of residual oxygen, and with it complete documentation of these parameters. At the same time, the new measuring method results in greater efficiency and higher quality.

The entry-level model among orbital welding power sources. The Mobile Welder enables automated welding of tubes for anyone and anywhere.

Lightweight and robust construction

The Mobile Welder is equipped with a carrying handle and shoulder strap and can be easily transported with a weight of approx. 15 kg. In addition, it convinces with a compact design.

Intuitive and simple operation

The Mobile Welder has the same intuitive operating concept as the Smart Welder series and is therefore equipped with a rotary dial, a touch display and soft keys. Clear and focused menu navigation allows the operator to create a welding program in just a few steps and then start the welding process. He is supported in this, for example, by the integrated auto-programming function. The Mobile Welder is equipped with all the important functions required for orbital welding. Together with our open, gas-cooled orbital welding heads, orbital welding can be carried out very easily and flexibly.

Manual TIG welding

The use of a "manual welding mode" is also possible in combination with a TIG hand torch, thus extending the application possibilities of the Mobile Welder. Tacking work can be carried out flexibly and manual welding can be carried out easily in places that are difficult to access with orbital welding heads. The simple and flexible changeover of the user interface between orbital and manual welding eliminates the need for an additional manual power source. The Mobile Welder offers the ideal 2-in-1 solution.

Upgrade options

It is always possible to expand the Mobile Welder's range of functions via upgrade options, should, for example, the requirements and areas of application of the welding work change. These upgrade options are available:

With these two upgrade options, the Mobile Welder is able to evolve into a Mobile Welder OC Plus and grow with the challenges.

Ready to Weld-Package

Don't wait - get started right away with the Ready to Weld-Package . The package contains everything needed for orbital welding: Mobile Welder, open MH weld head, and all the necessary connecting cables and hoses. In addition, the package offers an attractive price advantage over the individual components.

Do you want to produce consistently high-quality welds regardless of your location? With the Mobile Welder OC Plus, you can master any challenge in modern pipeline construction.

The Mobile Welder OC Plus is the first portable orbital welding power source designed specifically for use on the construction site. The Mobile Welder OC Plus brings the usual high and consistent quality of orbital welding to even the most remote locations.

The lightweight and robust design is equipped with state-of-the-art information and communication technology and builds on the strengths of the Orbimat 180SW - our established Smart Welder.

In addition, the Mobile Welder OC Plus impresses with its ease of use and minimal setup and training requirements.

The Mobile Welder OC Plus relies on the same software platform as our OM180SW. This allows for immediate changeover by trained personnel and seamless program exchange between machines.

The Mobile Welder OC Plus is supplied together with the ORBICOOL MW cooling unit, which is connected in just a few steps and can then be used anywhere on a mobile or stationary basis in production.

This flexibility is extended by the integration of a "Manual Welding Mode" in combination with the possibility to operate a hand torch - a power source for all challenges in modern pipeline construction.

This intelligent power source combines the orbital welding process with state-of-the-art information and communication technology and ensures the best welding results, high efficiency and sustainable quality management.

Centralized access to projects and parameters:

The Smart Welder can be integrated into the network via the integrated LAN interface: All welding data and programs of each individual weld can be seamlessly retrieved and documented, analyzed and adopted or optimized for future welds. Production processes can thus be better planned, and are also safer as well as more cost- and time-efficient.

Intuitive operation and multilingual menu interface:

Smart Welder power sources are operated via the large 12.4" color touch display or alternatively with the multifunctional rotary control, as known from premium automobiles and from the ORBIMAT CA series. The graphic-supported, multilingual menu interface enables simple and intuitive operation and parameterization of the welding power source. Important commands can be called up directly via softkeys.

More quality and safety:

More quality is achieved by the Smart Welder due to the digital and precise welding gas control, the "PERMANENT-GAS" function. This enables welds of the highest purity with low gas consumption, which reduces the cost per weld. The gas quantity values stored in the welding program thus lead to reproducibly good welding results. With the automatic rotor stop function, this results in greater safety.

Shorter welding cycles and higher productivity:

To minimize gas pre- and post-flow times, ORBITALUM has integrated the unique flow-force function, which decisively shortens the welding process when using closed welding heads. Thanks to the digital gas control, shielding gas is fed directly from the pressure reducer into the welding head at a very high volume flow rate - the unwanted residual oxygen is flushed out in an impulsive manner.

The resulting reduced preflow and postflow times result in significantly shorter process times and thus higher productivity and increased duty cycle. The high flow rate in the afterflow period and the optionally adjustable cooling circuit delay reduce the weld head temperature - ideal for high duty cycles.

Among other things, this results in a longer service life of the welding electrode. The optionally adjustable permanent gas function

prevents oxygen from entering the welding head even during non-productive times. As a result, the Smart Welder achieves virtually tarnish-free seams while keeping process times low.

For the finest in pipe & tube cutting, beveling and orbital welding products.

Orbitalum Tools GmbH is the world's leading supplier of complete industrial solutions for the precise cutting and beveling of tubes and for orbital welding. From weld seam preparation to the finished orbital weld seam - at Orbitalum Tools GmbH customers receive everything from a single source. Our products are characterized by easy handling, highest quality and industry-leading technology.

The products are mainly used in the food and beverage, chemical, pharmaceutical and semiconductor industries as well as in the aerospace industry. We are constantly developing innovative and customer-oriented solutions and offer a wide range of products.

The ITW Orbital Cutting & Welding group stands for the best, most efficient technology for all aspects of orbital cutting and welding around the globe.

As ITW OCW we provide an almost unique product availability, a worldwide customer service and technical support as well as a sales network at local level.

A partnership with ITW OCW involves:

ITW Orbital Cutting & Welding continues the Orbitalum and E.H. WACHS tradition of offering world class products, combined with exceptional service and support, to keep ITW-OCW the supplier of choice for tools used to cut - prep - weld - all from one source.

Plan your visit to the trade fair!